The year 2020 has been a very uncertain and a volatile year for industries and supply chains across the globe facing challenges right from global trade to natural disasters and pandemics. Such times call for a need to develop a resilient supply chain, for organizations to be able to adjust plans quickly and efficiently. Through this article, Prof. Anjali Shishodia offers you the resilience toolkit to reimagine supply chains through resilience.

GLOBALIZATION, since the last three decades, has increased the complexity of supply chains. The global interconnectivity of organizations has not only led to achieving profits but has also exposed them to several unprecedented supply chain disruptions such as Brexit, the US-China trade wars, climate change risks, and cargo thefts to name a few. The risk mitigation processes in organizations predominantly focus on predicting the known-unknown threats and mitigate them by implementing strategies for handling disruptions.

Most of these solutions are temporary answers to much bigger problems that catches the practitioners unaware. Nowadays, the supply chains need to be risk resilient and not risk blind for responding to the emerging unknown risks such as the recent pandemic. There is a lack of visibility caused by traditional technology as it hinders the transparency of end-to-end supply chains at the order, product, and shipment points. The data provided by the primitive and obsolete technologies leads to inaccuracy in planning, predicting higher fulfillment costs and difficulty in managing risks. Most of the SCM practitioners rank supply chain visibility as one of the biggest challenges which they face. The complex global supply chains demand a paradigm shift from traditional risk management thinking to address these vulnerabilities, uncertainties, and unforeseen disruptions. The linguistic meaning of the term ‘resilience’ is derived from the Latin word resiliere, which means the ability to ‘bounce back’ but the underlying core concept is “ability of a system to return and restore its original state after disruption”. Resilience, therefore, represents an opportunity for firms and constitutes something that firms should maximize in order to avoid disruptions.

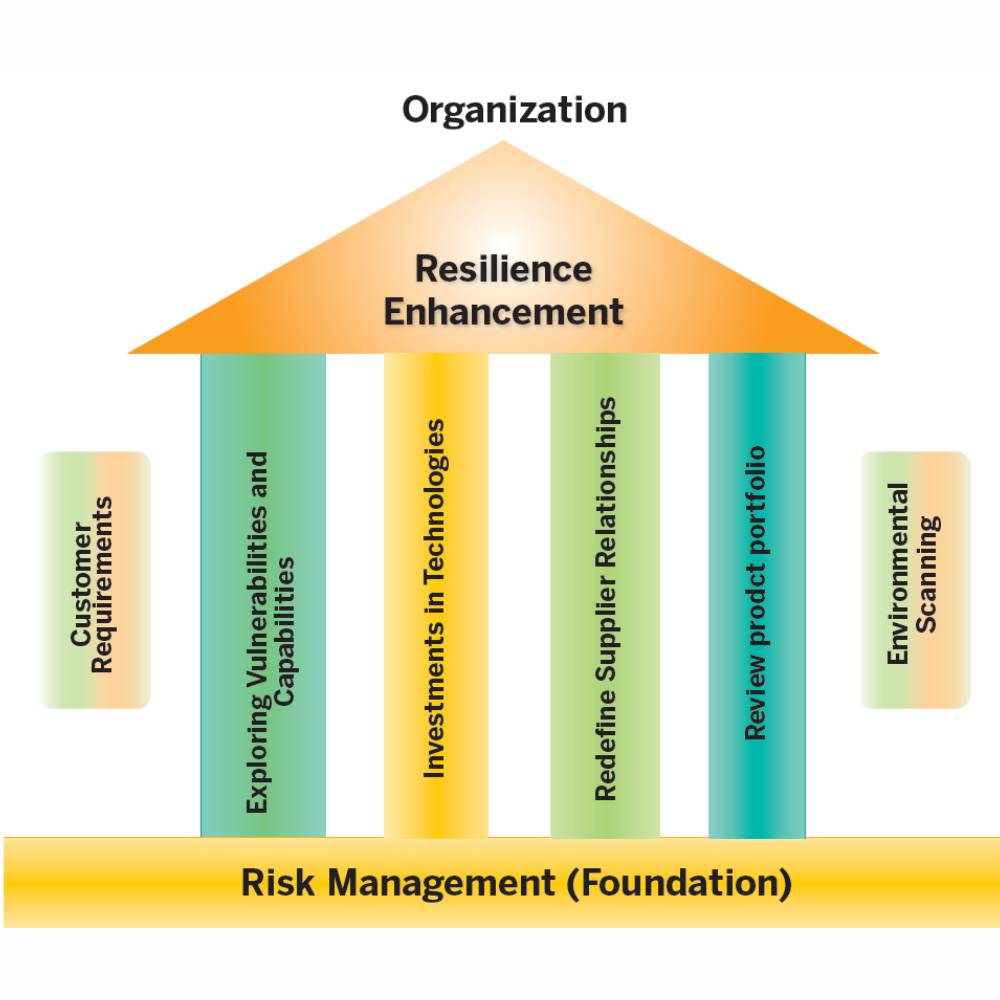

As the risk management toolkit helps the organizations to deal with known risks, a resilience enhancement toolkit can help organizations to effectively recover from unknown risks. The resilience toolkit may comprise of several dimensions that include exploring vulnerabilities and capabilities of the firm, building transparency through investments in analytics and digital supply chain capabilities, redefining supplier relationships, and reviewing their product portfolio. Following are the four vital strategies that organizations should deploy in order to possess a resilience toolkit in order to overcome disruptions in their supply chains:

TO EXPLORE VULNERABILITIES AND CAPABILITIES OF THE FIRM

As it is highlighted in a SWOT analysis chart, organizations must focus on improvising their internal capabilities and strategize on the opportunities. Weaknesses and threats or vulnerabilities often refer to a system’s resistance in preparation before the occurrence of a disruptive event aka catastrophe. On the contrary, recovery is defined as how the system or the organization adapts to situations when disruption occurs and how to get the system back on track until normalcy prevails. Vulnerability and time to recover are two critical dimensions of resilience, and the primary underlying difference between the two dimensions is the occurrence i.e. before and after disruption occurs.

Hence, vulnerability and time to recovery both constitute resilience, which enable a resilient system or an organization to better respond during the whole event of a disaster or disruption. Research studies outline that risk is something that firms need to minimize because it represents a threat. Therefore, lack of availability or ineffectiveness of key resources, practices, processes, or procedures highlights these as barriers to building resilience. These barriers obstruct firms in providing quick reaction to disruption and therefore increases vulnerability. Hence, resilience represents an opportunity for firms and constitute something that firms should maximize in order to avoid such disruptions. Therefore, an ecosystem should be developed comprising of flexibility, agility and adaptiveness in order to combat risks.

INVESTMENTS IN ANALYTICS AND DIGITAL SUPPLY CHAIN CAPABILITIES TO ACHIEVE SUPPLY CHAIN TRANSPARENCY

The transcendent of big data is big data analytics in which advanced analytic techniques are applied to provide business intelligence to the organizations. Big data analytics can enhance firm performance in the digital business environment. Ever since the concept of big data was introduced by Cox and Ellsworth in October 1977, since then it has gathered a lot of attention from both academia and practitioners. It has led to a growth in the implementation of supply chain technologies and has created a management shift from traditional decision-making to data-driven decision making.

The current supply chain management (SCM) practices are confronted with technological innovations and disruptions which constantly metamorphize the current supply chain configurations. Supply chain analytics (SCA) defines the amalgamation of SCM with big data analytics. Big data coupled with SCA plays a pivotal role in transforming and improving the functionality of the supply chains. This emergence of big data and supply chain analytics is the new frontier for the big data-driven supply chains as it has the potential to increase the value delivered to customers.

Nowadays digital supply chains are becoming a key enabler for achieving competitive advantage, with the upsurge in the advancement of ICT technologies, supply chains are now empowered to regulate the data flow and are oriented towards accumulating and analyzing big data for management efficiency. Digital supply chains can potentially lead to enhancement in organizational efficiency and effectiveness through activities such as location tracking, exchange of commodities, advanced demand forecasting and supply planning, and interpreting consumer and supplier behavior. A digital supply chain will lead to enhanced visibility throughout the supply chain, thereby reducing errors and redundancies which are aplenty in the conventional supply chains.

The digital supply chain investment capabilities depend upon organization expectations and degree of resilience required in an organization. The associated costs and benefits may be initially high but can be helpful in sustaining them better than their competitors in the longer run. Beyond the top-level generic strategies, the organization should think on the specific data required to be captured and measured using the best set of indicators. Also, careful investigation is to be done on under what circumstances particular strategies to be utilized to mitigate types of risks. This would help in effective budget allocation for reinventing the current business model. Organizations can have early supplier involvement to work closely with them for maintaining transparency. Organizations are not required to disclose every detail to their suppliers, but certain details such as inventory levels, network planning, and capacity can be disclosed and planned in collaboration for improving the supply chain visibility. This further helps in mitigating, avoiding, and transferring risks to a great extent.

REDEFINING SUPPLIER RELATIONSHIPS

It is high time to focus on redefining supplier relationships and capturing new opportunities from cross-industry models to reduce emerging risks. The focus should be shifted more on risk competitiveness rather than on cost competitiveness. The practitioners need to understand the structure and develop an issue hierarchy for identifying the hidden patterns, linkages, and nodes of interconnectivity that invite vulnerability. The organizational culture also acknowledges that warning signs of both internal and external risks to be openly shared. Management and employees need to feel empowered for putting up their opinion on how to convert challenges into opportunities. This would create an ownership environment for the outcomes of actions and decisions in the adversity and work harmoniously towards a rapid resolution.

Supply chains have ever been increased in length and complexity; therefore, resilience is considered as a critical capability for maintaining the continuity of operations and supply chain risk control along with timely and cost-effective product delivery. Resilience increases with the increase in coordination between the internal processes, real time information flow, greater coordination with the upstream and downstream partners. Therefore, it becomes significant to strategically select suppliers associated with the dedicated supply chains across primary (cost, quality, and lead time), green (carbon footprint and environmental practices) and resilient (absorptive, adaptive and restorative capacities) criteria to meet the end consumer needs. More focus should be laid on empowering local suppliers and developing shorter local supply chains.

REVIEWING THEIR PRODUCT PORTFOLIO

Majority of the organizations are in a rush for launching and extending their products/ services and commodities for acquiring market share and showcasing their presence. This may lead to increased sales and maximizing profits but can result in major flaws leading to product and project risks. Therefore, a strategic focus is needed to reduce product portfolio complexity that may increase sales volatility and operational costs. This also leads to an imbalance between the risks and costs associated with product and project portfolio leading to losses. Moreover, organizations should focus on their product portfolio through internal and external feedback so as to increase profits. Internal and external feedback largely depends upon supply chain integration and supply chain integration is enhanced through effective communication between the stakeholders in a supply chain. Information and communication technology tools also play a critical role in enhancing the supply chain integration. Based upon internal and external feedback, the products can be designed and launched. Effective supply chain integration also increases the risk mitigation capabilities in the organizations. Therefore, organizations must review their product portfolio and enhance supply chain integration through effective communication to increase their resilience capabilities.

SOME FOOD FOR THOUGHT

The dynamic turbulent business environment has forced the organizations to take measures for improvising their supply chains. Gone are the days when risk management was given utmost priority. Nowadays, more critical than risk management is the resiliency of the organization or their ability to bounce back after a catastrophe/ disruption. The resiliency toolkit will help the organizations to make decisions to enhance the resiliency capability and therefore make them prepare well in advance thereby saving vital resources. A resilient organization will be able to cope up with the external environment in the best way possible and will also have an enhanced customer centricity. The four vital strategies viz. explore vulnerabilities and capabilities of the firm, Investments in analytics and digital supply chain capabilities to achieve supply chain transparency, Redefining supplier relationships, and Reviewing their product portfolio are built on the foundations of risk management. Together, these strategies in synchronization can drive the organization towards resilience and thereby give the requisite ability to bounce back in case of disruptions. The organizations should proactively develop mitigation plans for potential slowdowns, shutdowns, and project restarts if any. Further, the organizations should focus on designing and shoring up contracts for limiting the risks associated with uncertain schedules as these can be positioned for efficient remobilization once recovery starts. Finally, the organizations need to develop coping capacity and adaptive capacity in order to learn, adapt and transform continuously with the business environment.

Categories

Magazine Editions