“In FMCG, product moves with high speed. Product should be available at shelf when customer requires it. Stock-out will directly lead to sales loss. It is very critical to maintain service with optimum inventory and in such a scenario, quality, cost and service become the key parameters. Newness, promotions, renovations, weight changes, standardizations, innovations need to be monitored very closely to maintain better availability,” asserts Umesh Joshi, Senior Supply Chain Professional, during an interview…

How has been the supply chain transformation taking place in the country over the years?

Supply chain function was earlier part of either finance or sales, now it is an independent function, which itself reflects its growing importance in the overall business strategy. In most of the organizations, it is reporting directly to MD or CEO. Today customer service and order fulfillment have become prime objective. In lieu to this, most of companies have implemented ERPs, planning system and migrated to collaborative SCM tools. Supply chains are becoming much leaner over the years and is playing a key role in capturing correct demand, design optimized network and executing required production and demand plan.

Supply chains are becoming more agile and efficient based on type of segment they are operating in. As the economy is growing, more innovation happening in supply chain. It has societal roles in sustaining human life like lot of work is happening in health care, food and cold supply chain. In a nutshell, times have changed from what we were used to seeing decades ago.

What are the weak links and how can we mitigate them?

Any link in supply chain which can reduce the throughput is a weak link. It may be physical or policy constraint. Each company needs to study their system and debottleneck the constraint. Weak links need additional buffer to mitigate. Some weak links are incorrect forecast, not having good primary and secondary distribution system. Other types of weak links are supply and price risk. Prices of raw materials get impacted due to disruption in supplies owing to natural diversities, terrorism, political instability, labor and dock strikes, etc.

You have been a part of one of the most complex industries – FMCG. How complex is the scenario?

In 2016, FMCG market was $49 billion and by the year 2020, the figure is estimated to be $104 billion. Typically, in FMCG sector, around 19% revenue is generated by food and beverages, 31% from health care, and 50% comes from household and personal care. In FMCG, product moves with high speed. Product should be available at shelf when customer requires it. Stock-out will directly lead to sales loss of any FMCG. It is very critical to maintain service with optimum inventory and in such a scenario, quality, cost and service become the key parameters. Newness promotions, renovations, weight changes, standardizations, innovations need to be monitored very closely to maintain better availability.

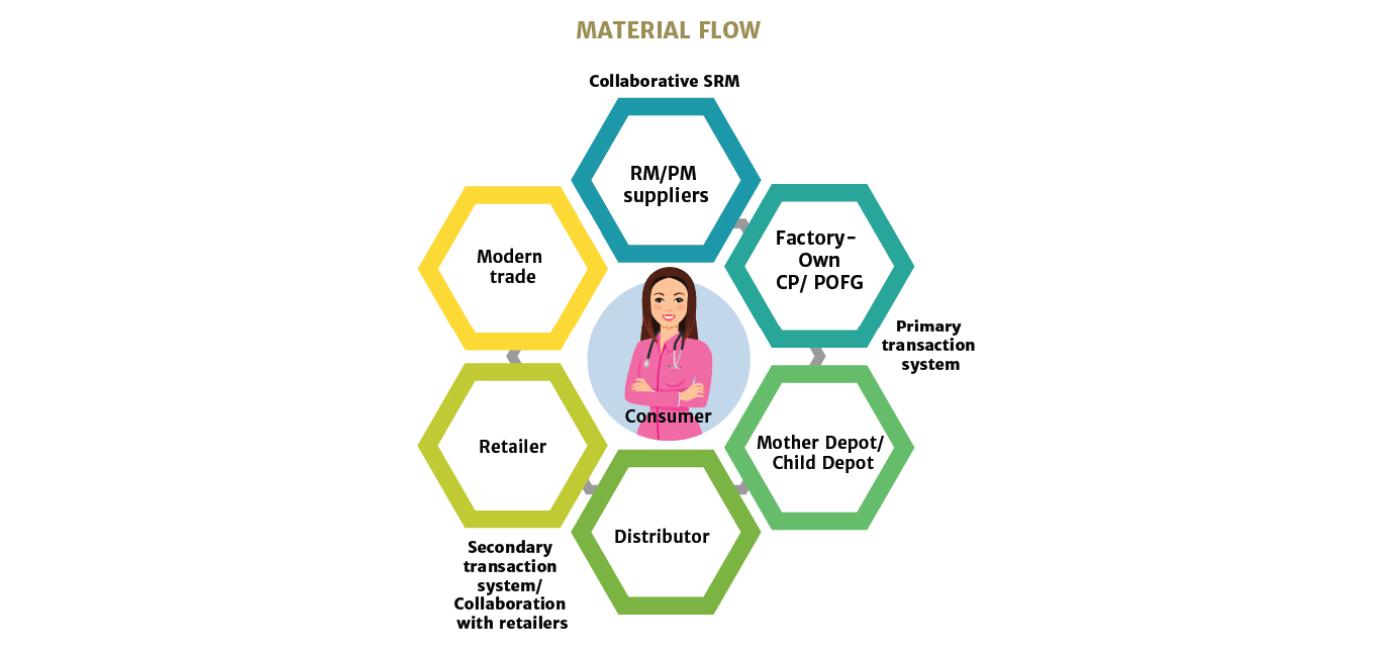

FMCG supply chain should be the most efficient, typically margins in FMCG are lower, most of the products do not require high technology. Key element in FMCG is branding and distribution because it works on the simple philosophy, ‘What people watch, listen and buy’. There are approximately 70 lakhs outlets in the country today with modern trade outlets numbering around 4000. Reaching to these many outlets is a challenge. Setting up own secondary distribution model is again a big challenge, because still 30-40% of the secondary distribution happens via wholesalers. Getting visibility of sales from these unorganized retails is a big challenge. Companies like HUL, ITC, Britannia, Marico have invested significantly in technology to capture secondary sales. However, capturing tertiary sales can still be a task. In all these circumstances, brand loyalty of customer gets impacted if product is not available on shelf when he desires it and end up buying products of competitors. Competing with local players is a biggest threat for any large company. Media exposure also brings lot of complexity as most of us remember as to what happened with Nestle in 2015.

What are the innovative measures brought by you in streamlining supply chain?

Visibility is the key element in supply chain. We have brought lot of visibility in system from secondary sales to RM/PM supplier. We have done lot of automation in planning and execution system. I was part of SAP APO transition in 2007-2008 in ITC Ltd. I lead Britannia’s SAP APO implementation in 2012-13. Lot of work happened in integrated demand & supply planning. Initial first 2 months was big challenge and hiccup. All the lines of plan were touched by sales team, latter we published FVA (Forecast Value added) at each step. Best plan was demand planners forecast, post discussion with head sales and marketing, we got full buying from sales and marketing. Forecasts accuracy became far better than industry average. SAP APO has given ROI much faster. We have improved continuous replenishment system (CRS), started direct dispatch to the customer at many places where full truck load formation happens. Like in ITC, Atta moves directly from mill to the distributor. To improve the distributors’ return, we have implemented GTM/Zero days inventory concept in many metros. We have rolled SAP WMS in Britannia in one of most complex warehouses.

How has been the scenario with the GST coming in?

GST implementation is win-win for everyone in long run, initially there were challenging scenarios due to starting hiccups. Most of the companies are bringing benefits of GST to the customer. GST is easing out the distribution and over all cost reduction in supply chain. Most of the companies are saving in distribution cost due to GST. This year most of FMCGs reported double digit growth. As net sale is moving up, cost per kg is coming down and all the companies are passing on the benefits to customers. Tax collection for the government is touching 1lakh crores per month. Long haul trucks are covering higher distance, transit time has been reduced 10-20% in long haul routes. Most of companies are remapping their depots and customer network. Small depots are merged with larger depots. Today, there is no need to maintain warehouse in every state. All in all, there is overall benefit of this consolidation. To keep tax evasion under check and better monitor trade, GST Council has decided to launch E-way bill. E-way bill is solution to connect all stakeholders, suppliers, transporters, and recipients. It will bring lot of efficiency in system.

How can companies achieve supply chain network optimization?

Each company is focusing on cost saving initiatives, most of the companies are running cost efficiency programs. In Optimization, total delivered cost of the product should be minimum. Most of the FMCG companies follow Hub & Spoke model. They run long term capacity planning 3-5 years in advance to see their factory footprint and see how their demand clusters are growing. They try to utilize the existing capacity by creating more interchangeability in lines and maximum utilization of head room. Distance travelled is the most critical factor for bulky and low margin products.

Most of the companies take help from consultants to start the process, latter move the process to internal team. If any company has more factories, depots, SKUs and customer combinations, number of variables in optimization problem multiplies. This requires algorithms. Large companies run optimzation for quota/ sourcing allocation every month. If there is no addition of new factory, 85-90% souring map remains the same. If a new factory is added in the network, this exercise must be done again pre and post stabilization for new plant. Ideally speaking, every large FMCG must do network optimization for sourcing pattern at least once in a quarter.

Post GST implementation, lot of network optimization work is happening for depots and customer mapping. Government fiscal policies play a large role in setting up plant in fiscal zones. Maximum loading needs to be given to fiscal benefit factories. Now-a-days, companies are even focusing on last mile optimization.

FMCG supply chain best practices

Optimize the full network, supplier to customer

Improve the inventory velocity, increase the inventory turns

Have strong S&OP process implemented

Implement lean supply chain practices

Implement pull system for high demand variability SKUs, only push stable demand SKUs

Use technology, implement best CPFR tools for suppliers and customers

Monitor cost and other KPIs on a regular basis

Reduce distance travelled for product, improve vehicle utilization, keep balance between service and cost.

Inventory optimization seems to be one of the biggest segments when it comes to supply chain. How can we achieve this?

Yes, inventory is a part of working capital of the company and this is one of the large portions of the cost. By selecting least cost lanes and optimum service levels, holding the inventory at the highest node will reduce the overall inventory. When demand variability and number of products are very high, TOC model is the best for replenishment. If we increase the service frequency to the customers, they can manage with less space, less overheads, better freshness, low damage. It gives better return to the customers. When you increase the service frequency with smaller lot supply chain cost increases. If as business case better service brings more sales, lean model needs to be implemented. Inventory policy should be based on service level desired, demand and supply variability.

Multi-echelon inventory model is the best approach to optimize inventory in full network i.e., plants, depots and customers. Biggest opportunity in this is to reduce skewed primary and focus more on secondaries. If demand and supply variabilities reduce, you can manage with uniform inventory. Implantation of pull based CRS (continuous replenishment system) will reduce variability in the system. Companies like HUL, ITC, Britannia, Marico follow typical replenishment model, while on the other end, GCPL (Godrej Consumer Products Ltd), Pidilite, VIP, Bajaj Electricals, etc., work on the TOC model where you hold maximum inventory at RDCs and replenish as pulled by actual sales.

How is technology transforming the supply chain landscape? What are the new tech tools that are shaping the future?

Technology has brought lot of online data visibility from capturing the demand from market to communicate purchase order to the vendor. Lot of applications are getting implemented in digital space. Digital applications can improve service, cost, agility, and inventory. Tools such as GPS, RFID, EDI are helping companies in a big way. Companies are moving towards setting up supply chain control towers where decisions can be made quickly based on real time data.

What’s your take on infrastructural bottlenecks and how is the scenario shaping up now?

Poor infrastructure leads to long lead times, more transit damage and more inventory in the system. Many products with low shelf life are unable to reach to market on time due to poor infrastructure. Over the last 2-3 years, the government is putting lot of emphasis on infrastructure. Post GST, lot of 3PLs are coming with better infrastructure for warehousing, which will lead to better efficiency in supply chain.

What are the peculiarities you find in today’s young talent and professionals?

Today’s young talent is much smart, tech savvy and acquainted with latest tools. Operations and supply chain is taught in all B-schools and more professional talent is available these days. These days knowledge and information is available on the finger tips. Today’s professionals have better opportunities and platform to show their potential and talent.

My only message to new age professionals is to see the full picture, connect the dots how supply chain can help to increase sales and reduce cost. Company goal is first, department goal is second, self-objective is the last. Scope of work in supply chain area is increasing, there are wide range of roles available in supply chain now-a-days. One should do one role at least for 3 years for better understanding of the role before jumping on to another role to master the subject. Try to create legacy in any role.

How do you foresee the Indian economy and its subsequent impact on the logistics & supply chain segment going ahead?

There are notable trends being witnessed in the FMCG domain currently, which include: Product innovation, premiumization, product customization, brand consciousness, expanding horizons, focus on rural market, expanding distribution networks, third-party manufacturing, rising importance of smaller-sized packs, increased hiring from tier II/III cities, increasing private label penetration, etc., which are slated to ride the growth in times to come.

As the Indian economy grows, consumption of goods & services will increase. There will be better infrastructure in the country. The Central Government announced its plans to spend $9.16 billion for creating more jobs opportunities in the rural sector, which will in turn propel demand for FMCG products.

Currently supply chain cost is 4-10% of net sales value of the product in FMCG sector. As the demand will move up, cost of servicing per kg will come down in industry, which will ultimately benefit the customer. Overall, service level will also improve.

Lot of investment is coming to national highways. Freight corridors are coming up in 15 states all over India. Government is planning to improve speed of goods trains and double to cargos over 2-3 years. 100% FDI is coming in free trade warehouse Zone schemes. Incentives such as duty free import of building materials and equipment are attracting investors as well as lot of investment is coming in cold chain sector. With such positive news around, we will have all the means & resources to better our supply chain network and lead the growth.

Categories

Magazine Editions